Choose a reliable manufacturer for Generic Cialis to ensure safety and effectiveness. Recognized names in pharmaceuticals prioritize quality control and adhere to stringent regulatory guidelines, ensuring their products meet high standards.

Look for manufacturers that produce Generic Cialis in cGMP-compliant facilities. This certification indicates rigorous adherence to Good Manufacturing Practices, significantly reducing the risk of contaminants and ensuring consistent potency in their medications.

Evaluate the reputation of the manufacturer based on customer reviews and clinical studies. Transparent companies often provide comprehensive information about their production processes and ingredients, allowing consumers to make informed decisions. By selecting a reputable supplier, you can gain confidence in the efficacy of the product.

Lastly, consider sourcing Generic Cialis from manufacturers that offer a range of dosage options. This flexibility allows healthcare professionals to tailor treatments according to individual needs, enhancing patient satisfaction and treatment outcomes.

- Generic Cialis Pharmaceutical Manufacturer

- Overview of Generic Cialis and Its Uses

- Key Generic Cialis Manufacturers Worldwide

- Other Notable Manufacturers

- Manufacturing Process of Generic Cialis

- Quality Control Standards for Generic Cialis Production

- Testing and Validation Procedures

- Regulatory Compliance and Documentation

- Market Comparison: Generic Cialis vs. Brand Version

- Effectiveness and Formulation

- Side Effects and Recommendations

- Regulatory Approvals and Compliance for Manufacturers

- Key Regulatory Steps

- Post-Approval Compliance

Generic Cialis Pharmaceutical Manufacturer

When selecting a generic Cialis manufacturer, prioritize those with a reputation for quality and regulatory compliance. Companies like Teva Pharmaceuticals and Mylan are well-known for producing reliable generics that meet stringent international standards.

Check the manufacturer’s certifications and approvals from reputable authorities such as the FDA or EMA. These certifications ensure that the production processes align with safety and quality regulations.

Pay attention to the formulation of the generic product. Trusted manufacturers often provide detailed information about active ingredients and dosages. Transparent labeling allows for informed choices, enhancing user confidence in the product.

Consider customer reviews and feedback. Manufacturers with a strong track record often have positive testimonials from users. This social proof can assist in assessing effectiveness and user satisfaction.

Pricing is another key factor. Reputable manufacturers offer competitive prices without compromising on quality. Compare costs while ensuring that the products come from established suppliers to avoid counterfeit medications.

Lastly, consult with healthcare professionals when making a decision. They can provide valuable insights and recommendations based on specific medical needs, guiding you to the most suitable manufacturer for generic Cialis.

Overview of Generic Cialis and Its Uses

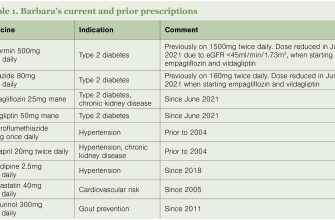

Generic Cialis primarily serves to treat erectile dysfunction (ED). Its active ingredient, Tadalafil, enhances blood flow to the penis, enabling a stronger and longer-lasting erection after sexual stimulation.

Key uses of Generic Cialis include:

- Erectile Dysfunction Treatment: Provides relief for men experiencing difficulty achieving or maintaining an erection.

- BPH Management: Alleviates symptoms of benign prostatic hyperplasia (BPH), such as frequent urination and difficulty urinating.

- Pulmonary Arterial Hypertension: Improves exercise capacity in adults with this condition by relaxing blood vessels in the lungs.

The recommended starting dose for most patients is 10 mg, taken before anticipated sexual activity. Depending on individual response and tolerance, the dose may be adjusted. For daily use, a lower dose of 2.5 to 5 mg is often advised to maintain a consistent level of medication in the body.

Side effects may include headache, back pain, muscle aches, and flushing. Most effects subside within a few hours. If any serious side effects occur, such as sudden vision loss or an erection lasting more than four hours, immediate medical attention is necessary.

Always consult with a healthcare provider before starting Generic Cialis to ensure it is a suitable option based on personal health history and other medications being taken.

Key Generic Cialis Manufacturers Worldwide

Several leading manufacturers produce generic Cialis, offering a range of options for consumers. Teva Pharmaceuticals stands out as a significant player, known for its consistency and reliability in medication quality. They provide a variety of dosage forms, ensuring accessibility for patients. Another prominent manufacturer is Mylan, which has established a solid reputation in the pharmaceutical industry, providing competitively priced generic Cialis without compromising on quality.

Other Notable Manufacturers

Ranbaxy Laboratories also plays a key role in the generic Cialis market. Their commitment to producing affordable medications makes them a favored choice among many users. Additionally, Aurobindo Pharma is gaining traction due to its robust distribution network and focus on generics, allowing for broader access to erectile dysfunction treatments. These manufacturers contribute significantly to the global supply, making effective treatment options available to more people.

Manufacturing Process of Generic Cialis

The manufacturing of Generic Cialis involves several key steps to ensure quality and consistency. The primary active ingredient in Cialis is Tadalafil. The process begins with sourcing high-purity raw materials from verified suppliers. Each batch of raw materials undergoes rigorous quality checks, including chemical analysis, to confirm their identity and purity.

Once the raw materials are validated, they are processed in a controlled environment. The initial phase involves the synthesis of Tadalafil. This is achieved through a series of chemical reactions that require precise temperature and pressure conditions. Skilled chemists monitor the reaction process to ensure optimal yields and minimize impurities.

After synthesis, the Tadalafil undergoes crystallization. This step is critical as it forms the necessary crystal structures for the drug. The crystallized Tadalafil is then filtered, washed, and dried to eliminate any residual solvents.

With the active ingredient prepared, the next step is formulation. Tadalafil is blended with excipients, which can include binders, fillers, and stabilizers. This mixture ensures that the final product retains the desired properties such as solubility and bioavailability. The formulation undergoes further quality testing to verify homogeneity and correct dosage.

Once the formulation is confirmed, the mixture is compressed into tablets. The compression process requires precision to achieve consistent tablet weight and hardness. After compression, the tablets are coated to improve their stability and enhance patient compliance by masking taste or odor.

Quality control is an ongoing process. Finished tablets are subjected to various tests, including dissolution testing, to ensure they release the active ingredient correctly in the body. These tests are performed according to regulatory guidelines to meet safety and efficacy standards.

| Step | Description |

|---|---|

| Raw Material Sourcing | High-quality raw materials are sourced and tested for purity. |

| Synthesis | Active ingredient Tadalafil is synthesized through controlled chemical reactions. |

| Crystallization | Tadalafil is crystallized to form proper structures for drug activity. |

| Formulation | Tadalafil is mixed with excipients to create the final formulation. |

| Compression | The mixture is compressed into tablets with consistent quality. |

| Coating | Tablets are coated for improved stability and patient compliance. |

| Quality Control | Finished tablets are tested to ensure safety and efficacy. |

This structured approach to manufacturing Generic Cialis helps maintain high standards in pharmaceutical production. Each phase is crucial for delivering a safe and effective product to consumers.

Quality Control Standards for Generic Cialis Production

Adhere to stringent quality control standards to ensure the production of Generic Cialis meets safety and efficacy benchmarks. Conduct raw material inspections to verify authenticity and purity, preventing any substandard components from entering the manufacturing process.

Testing and Validation Procedures

Employ rigorous testing protocols throughout the production stages. Initiate in-process quality checks, including particle size analysis and dissolution tests, to monitor the consistency of the final product. Validate analytical methods regularly to confirm their reliability, using calibrated equipment and certified reference materials.

Regulatory Compliance and Documentation

Maintain compliance with relevant regulations, such as FDA guidelines and Good Manufacturing Practices (GMP). Implement comprehensive documentation practices to track all quality control activities. This includes batch records, testing outcomes, and calibration logs, which provide transparency and accountability, crucial during audits or inspections.

Market Comparison: Generic Cialis vs. Brand Version

Choosing between generic Cialis and its brand version involves examining several key factors: cost, availability, effectiveness, and side effects. Generic Cialis often comes at a lower price point while providing similar therapeutic results. Consumers benefit from a significant cost reduction without compromising quality. Many insurance plans cover generic options, making them more accessible for a wider audience.

Effectiveness and Formulation

Both generic Cialis and the brand version contain the active ingredient Tadalafil, ensuring comparable performance in treating erectile dysfunction. Clinical studies demonstrate that users of generic Cialis experience similar satisfaction levels and effectiveness. However, minor differences in inactive ingredients may occur between the two formulations, potentially affecting individual tolerance. Users sensitive to specific components might prefer one version over the other.

Side Effects and Recommendations

The side effect profiles for both versions are largely identical, with common reactions including headaches, flushing, and indigestion. Personal health history can influence the choice of product. Consulting a healthcare provider ensures safe usage tailored to individual needs. Many individuals find purchasing generic options more economical, but brand-name products might offer added reassurance due to established branding. Ultimately, the decision often hinges on personal preference, budget, and any specific medical advice received.

Regulatory Approvals and Compliance for Manufacturers

Manufacturers of generic Cialis must adhere to strict regulatory approvals and compliance standards to ensure product safety and efficacy. Primary regulatory authorities include the Food and Drug Administration (FDA) in the United States and the European Medicines Agency (EMA) in the EU.

Key Regulatory Steps

- Preclinical Research: Conduct comprehensive research to assess safety and biological activity. Document all findings meticulously.

- Investigational New Drug Application (IND): Submit an IND to the FDA, providing data on preclinical studies, manufacturing processes, and clinical trial protocols.

- Clinical Trials: Execute Phases 1, 2, and 3 of clinical trials to gather data on safety, dosage, and efficacy. Compliance with Good Clinical Practice (GCP) is mandatory.

- New Drug Application (NDA): Upon successful trials, submit an NDA containing clinical data, proposed labeling, and manufacturing information for approval.

Post-Approval Compliance

- Good Manufacturing Practice (GMP): Adhere to GMP guidelines to ensure product quality during production, including facility hygiene and employee training.

- Adverse Event Reporting: Establish a system for monitoring and reporting adverse drug events to the relevant authorities.

- Periodic Review: Conduct regular reviews and updates of the drug’s safety profile and efficacy after market release.

Maintaining compliance with these regulatory requirements is not only a legal obligation but also a commitment to product quality and patient safety. Manufacturers should invest in training and resources to keep their teams informed about the latest regulatory developments and industry best practices.